What Sets Prestressed Panels Apart

What Makes Pre-Stressed Panels Different

The defining feature of pre-stressed panels is the pre-tensioning of steel reinforcement before the concrete cures. This process places the panel under internal compression, giving it the ability to carry heavier loads and resist cracking compared to standard precast elements.

Practical Advantages of Prestressed Concrete Panels on the Work Site

In practical terms, this means walls hold their shape as intended. Openings for windows, doors, and sills line up naturally. Adjacent panels connect cleanly, removing the need for on-site adjustments. Builders can rely on panels that behave predictably from delivery through installation, which streamlines workflow and reduces unexpected delays.

Longer Spans & Flexible Design

Because the stress is already integrated into the panel, prestressed concrete panels can span longer distances without additional support, allowing for creative and flexible floor layouts while maintaining structural integrity. Panels can be manufactured to custom heights, thicknesses, and lengths, providing a tailored fit for standard and complex designs.

Faster, Cleaner, More Reliable Workflows

On-Site Advantages of Prestressed Panels

Faster installation

Factory precision ensures panels arrive ready to fit, reducing the need for cutting or adjusting on site.

Reduced labour requirements

Pre-fabricated panels simplify assembly, decreasing the number of skilled workers required.

Material efficiency

Thinner panels carry the same load as thicker traditional walls, optimising concrete use without compromising performance.

Weather-tolerant construction

Unlike poured-in-place concrete, pre-stressed panels can be installed in a range of weather conditions without delaying schedules.

Durability and longevity

Pre-tensioning strengthens the wall internally, reducing the risk of cracking, deformation, or long-term maintenance issues.

Where Precast Concrete Performs Best

Applications of Precast Panels

No matter the project type, prestressed concrete panels simplify planning, installation, and ongoing maintenance.

Precast concrete panels are versatile and suitable for a wide range of construction projects. Common applications include:

Commercial buildings

Office blocks, warehouses, and retail spaces benefit from fast installation and high load-bearing capacity.

Residential projects

Multi-storey apartments, townhouses, and modern homes achieve precise alignment, clean lines, and durable walls.

Industrial facilities

Factories and storage buildings gain strong walls capable of supporting heavy equipment and long spans.

Institutional buildings

Schools, hospitals, and community centres benefit from speed and structural reliability.

Comparison

Pre-Stressed vs. Traditional Wall Panels

While traditional precast concrete panels are already a significant improvement over poured-in-place walls, pre-stressed concrete wall panels offer distinct advantages:

For contractors working in the variable climates of Northern Ireland and ROI, pre-stressed panels provide peace of mind, knowing walls will perform under stress while reducing the risk of future remedial work.

For Pre-Stressed Concrete Wall Panels

Technical & Material Considerations

Pre-stressed concrete wall panels are made from high-strength concrete mixes that are carefully cured to achieve optimal structural properties. Typical thicknesses are 100mm, 140mm & 180mm, depending on load requirements and building type. Pre-tensioned steel cables or rods are placed under tension before concrete casting, embedding stress that counteracts applied loads once the panel is in use.

- Superior tensile strength compared to conventional precast walls.

- Reduced shrinkage and cracking due to controlled curing.

- Predictable deflection behaviour under load, enhancing design accuracy.

- Compatibility with insulation layers and architectural finishes for energy efficiency and aesthetics.

Adaptable for Any Project

Design Flexibility & Custom Options

One of the most significant advantages of pre-stressed concrete wall panels is the ability to customise them to specific project needs:

Custom dimensions

Height, length, and thickness tailored to architectural and structural requirements

Window and door openings

Factory-cut to exact specifications for seamless installation

Surface finish options

Smooth, textured, or architectural finishes suitable for modern aesthetics

Integrated insulation

Panels can incorporate insulation layers to meet thermal performance targets

This flexibility makes pre-stressed concrete wall panels an ideal choice for builders in Northern Ireland, ROI, and the UK, where each project can demand unique structural or aesthetic considerations.

For Pre-Stressed Concrete Wall Panels

Technical & Material Considerations

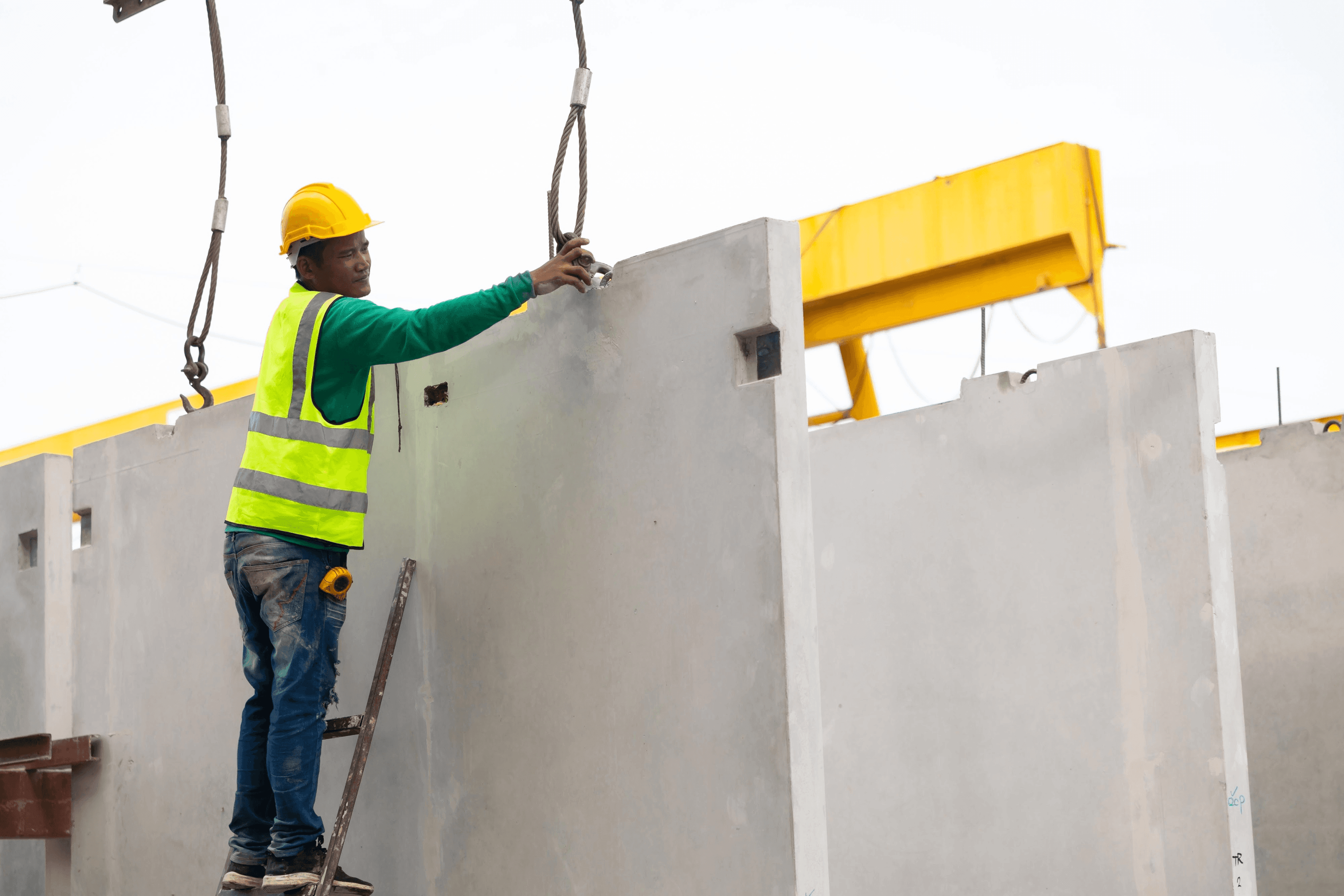

Proper handling and installation are critical to maximising the benefits of precast concrete panels. At McGarrity Bros. Ltd., we provide guidance on:

- Lifting and placing panels safely

- Sequencing for efficient construction workflow

- Aligning panels to foundations, floors, and other structural elements

- Securing connections for long-term performance

With our support, contractors can achieve faster build times and maintain the structural integrity of the project from groundwork to finishing touches.

Discover a Better Way to Build Walls with Prestressed Concrete Panels

We are happy to help and advise

Plan smarter, build faster, and reduce on-site surprises. Speak with our team at McGarrity Bros. Ltd. to review panel specifications, plan deliveries, or map out installation sequences tailored to your project. Every panel is made to fit; let us make sure it fits yours.